What is it?

The patented Blucomb micro-gasification burner consists of a steel reaction chamber where the pellet is manually loaded, and a system for mixing the combustion air with the combustible gases generated during the reaction.

Thanks to the arrangement of the air inlets, the ignition of the pellet at the top of the chamber triggers a controlled and homogeneous process of pellet pyrolysis supported by the natural draft of the chimney that can last for several hours without the need for refilling.

Particularly suitable for radiant heat stoves, the burner allows greater control of combustion parameters and allows the power output to be adapted to the heat storage and release capacity characteristics of the type and size of the appliance.

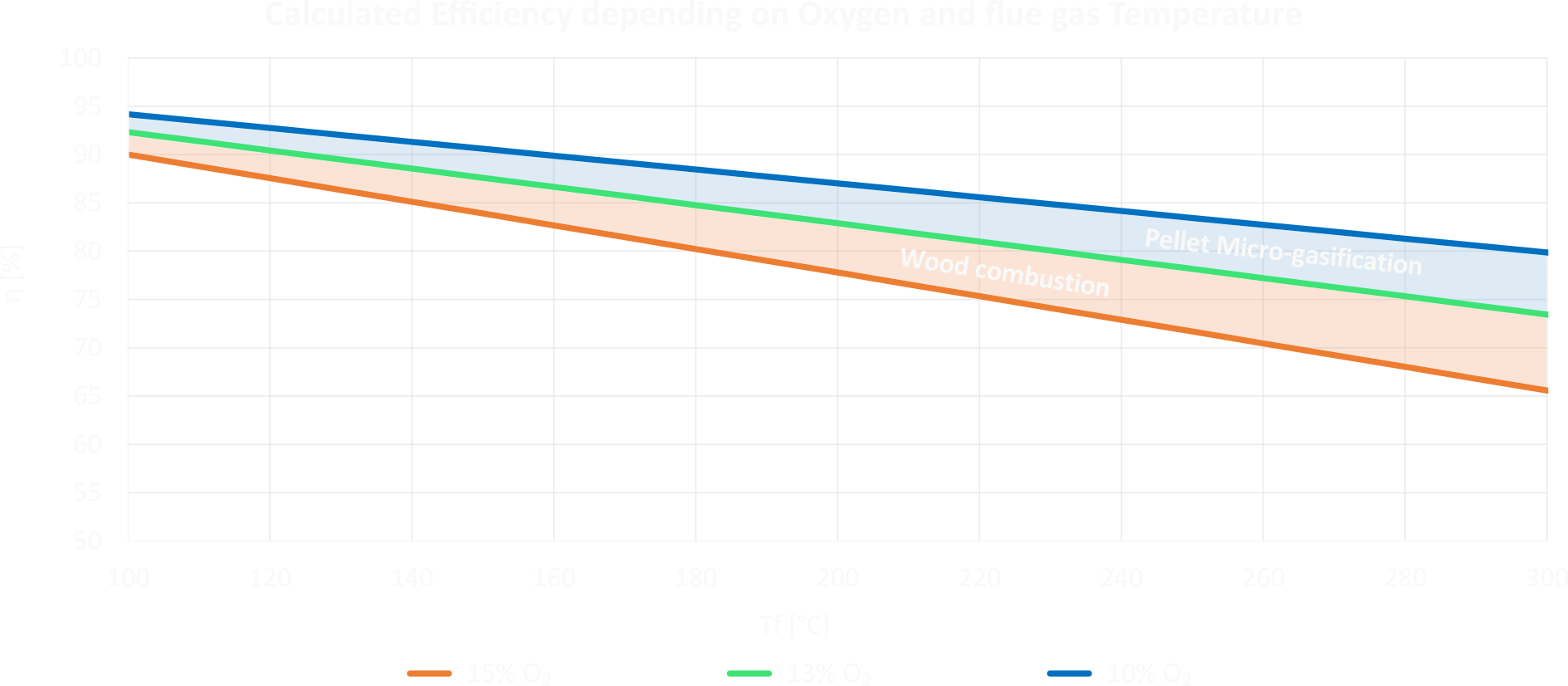

The combustion process achieved with Blucomb burners significantly reduces polluting emissions. In particular, the levels of carbon monoxide (CO), nitrogen oxides (NOx), volatile organic carbon (OGC) and particulate matter (PM) are well below the limits imposed by the most stringent industry standards.

If you want to see our burners in action at Progetto Fuoco 2024, you can visit the stands of the companies present here that use them.

Altech HALL 4 STAND B 55

Ofenhaus HALL 4 STAND A 26

Odin HALL 6 STAND E 28

Norsk Kleber AS HALL 6 STAND E 28

Assocosma HALL 5 STAND A 36

Services for Companies

Blucomb burners operate without electricity and can be inserted into a pre-existing compartment below the combustion chamber in most existing wood stove models, making them bi-fuel (wood/pellet). Integrating a Blucomb burner maximizes the stove’s efficiency and reduces polluting emissions to levels below the most stringent standards.

Blucomb offers support to companies in the sector for the design and prototyping of new stove models and the modification of existing ones to be equipped with our burners.

We can integrate or adapt our standard burners, or develop new models based on the characteristics of the stoves already in production, in order to minimize the necessary modifications.

In our laboratories, we carry out prototyping and analysis of combustion and efficiency preliminary to product certification.

In addition to offering support and technical assistance for the entire stove optimization process, we also follow the certification of the appliance according to the European standard EN 16510 and ECODESIGN in collaboration with our accredited partner laboratories. In this way, it is possible to deliver to the manufacturer a high-performance product ready for marketing.

Blucomb is also a highly specialized technological partner for the design of other innovative biomass combustion solutions.