The Blucomb micro-gasification burner belongs to the TLUD (top-lit up-draft gasifier) type. It consists of a steel reaction chamber (kiln) in which the biomass (wood pellets) is loaded, and a system for mixing the combustion air with the generated combustible gases.

Thanks to the arrangement of the air inlets, the ignition of the pellets in the upper part of the chamber triggers, in a few minutes, a controlled and homogeneous process of pyrolysis of the pellets supported by the natural draught of the chimney.

The pyrolysis process that is obtained inside the reaction chamber breaks down the molecules of lignin and cellulose, the main energy constituents of wood, transforming the pellet into combustible gas and coal.

At a later stage, it also transforms the coal into flammable gas, leaving a small amount of ash as the only solid residue of the process at the bottom of the reaction chamber.

The patented geometry of Blucomb’s micro-gasification burners regulates and directs the optimal air flows for a complete gasification process: the result is a significant improvement in combustion and a significant reduction in emissions and unburned fuel.

Thanks to this process, the flame layer that develops above the reaction chamber beyond the gas generation zone forces each fuel molecule to pass through it and oxidize completely.

Shortly after ignition there is a separation between the gas generation zone inside the chamber and the gas combustion zone at the upper outlet where, through suitable passages, the gas crosses a flow of combustion air and burns in an optimal way.

Combustion achieved with Blucomb micro-gasification burners significantly reduces pollutant emissions by ensuring much lower levels of carbon monoxide (CO), nitrogen oxides (NOx), volatile organic carbon (OGC) and particulate matter (PM) than any other conventional combustion.

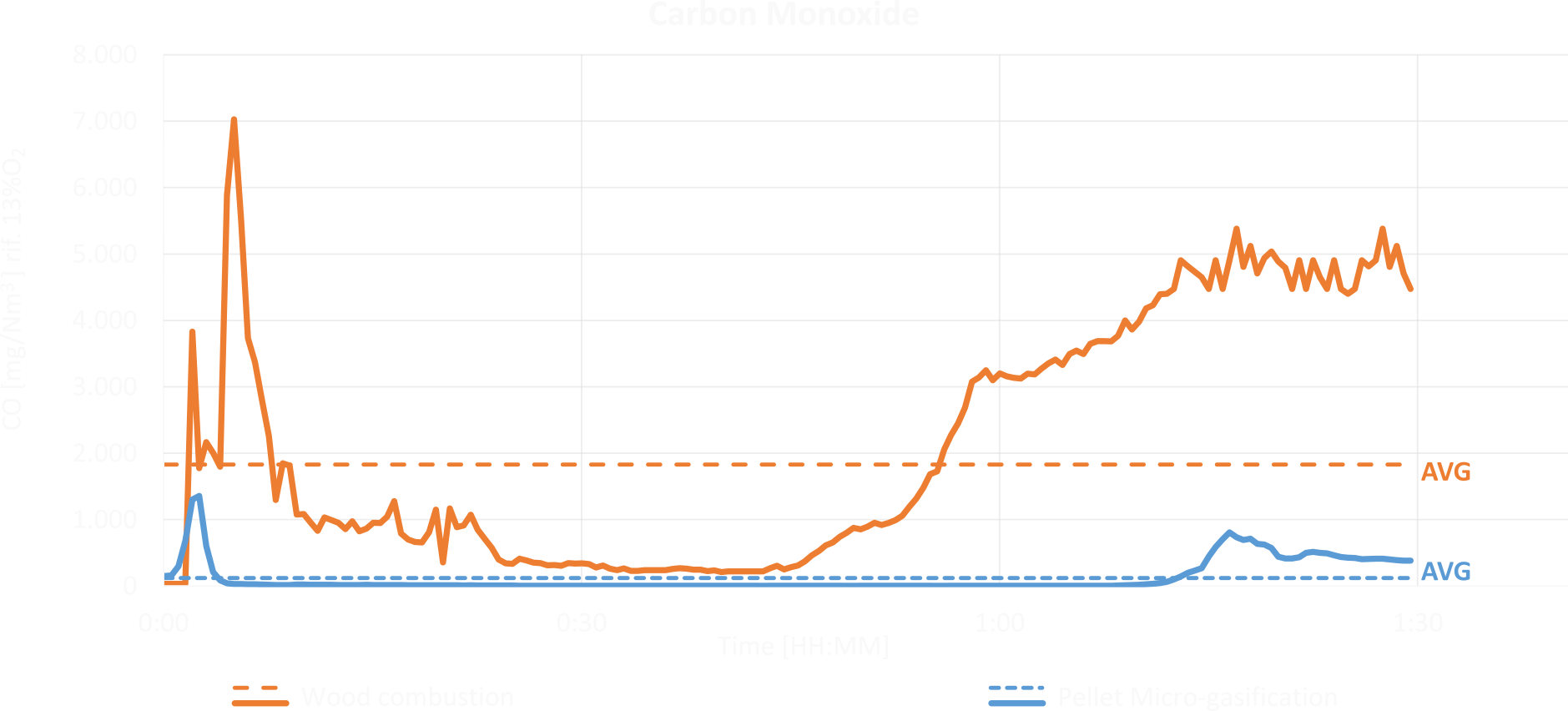

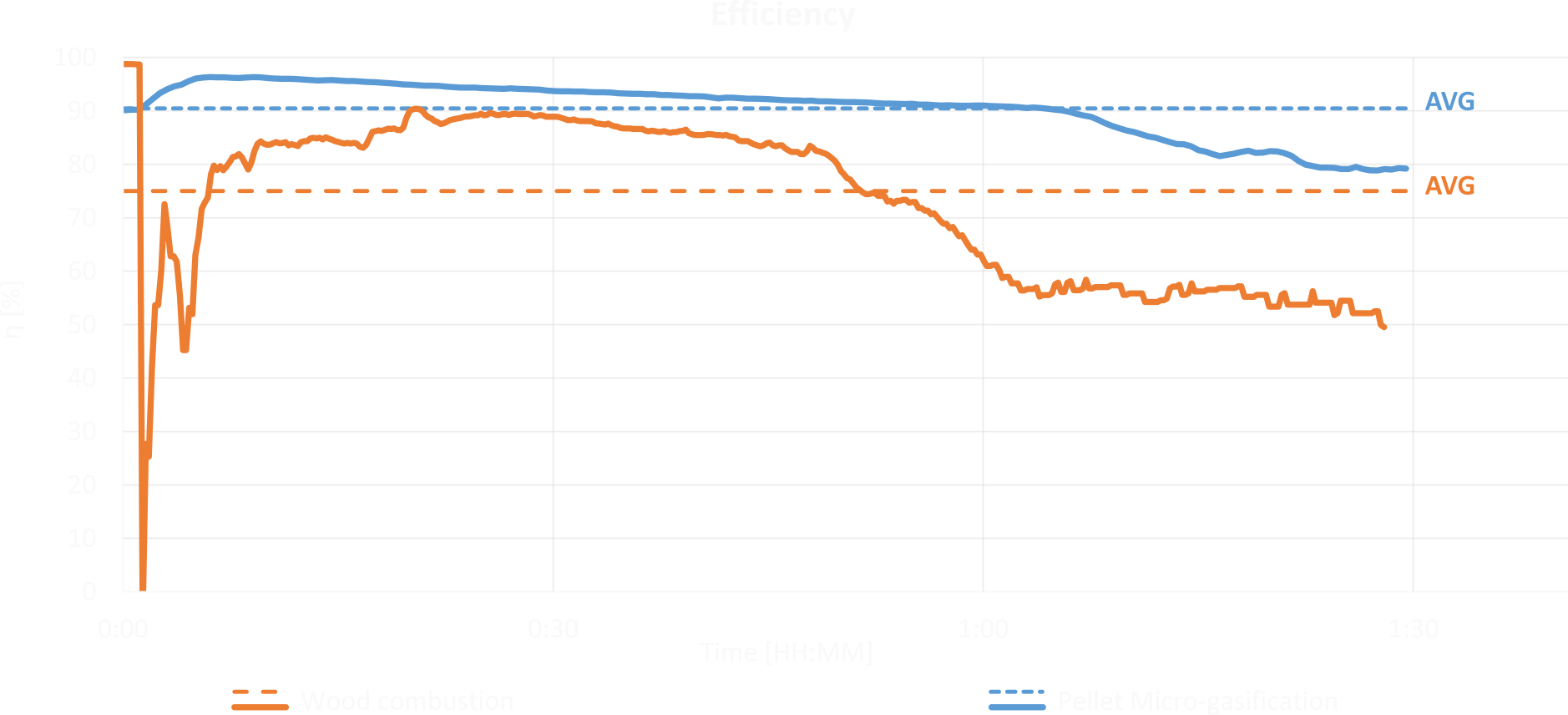

Below are some data from a comparison between wood and pellet burning with the Blucomb system. The data refer to combustion sustained within the same stove model. The measurement interval, which also includes ignition, is 1.5 hours and ends when the embers are almost completely extinguished.

The amount of carbon monoxide (CO) in the flue gas is one of most significant index of combustion quality. Its value measured in ppm (parts per million) must be as low as possible because its presence indicates that combustion has not been completed: in fact, each carbon atom can be oxidized by 2 oxygen atoms creating carbon dioxide (CO2) which is the main product of each type of combustion.

Our burners minimize the disadvantage of partial combustion by keeping the amount of CO at a few parts per million during the whole process, well below the strictest legal limits.

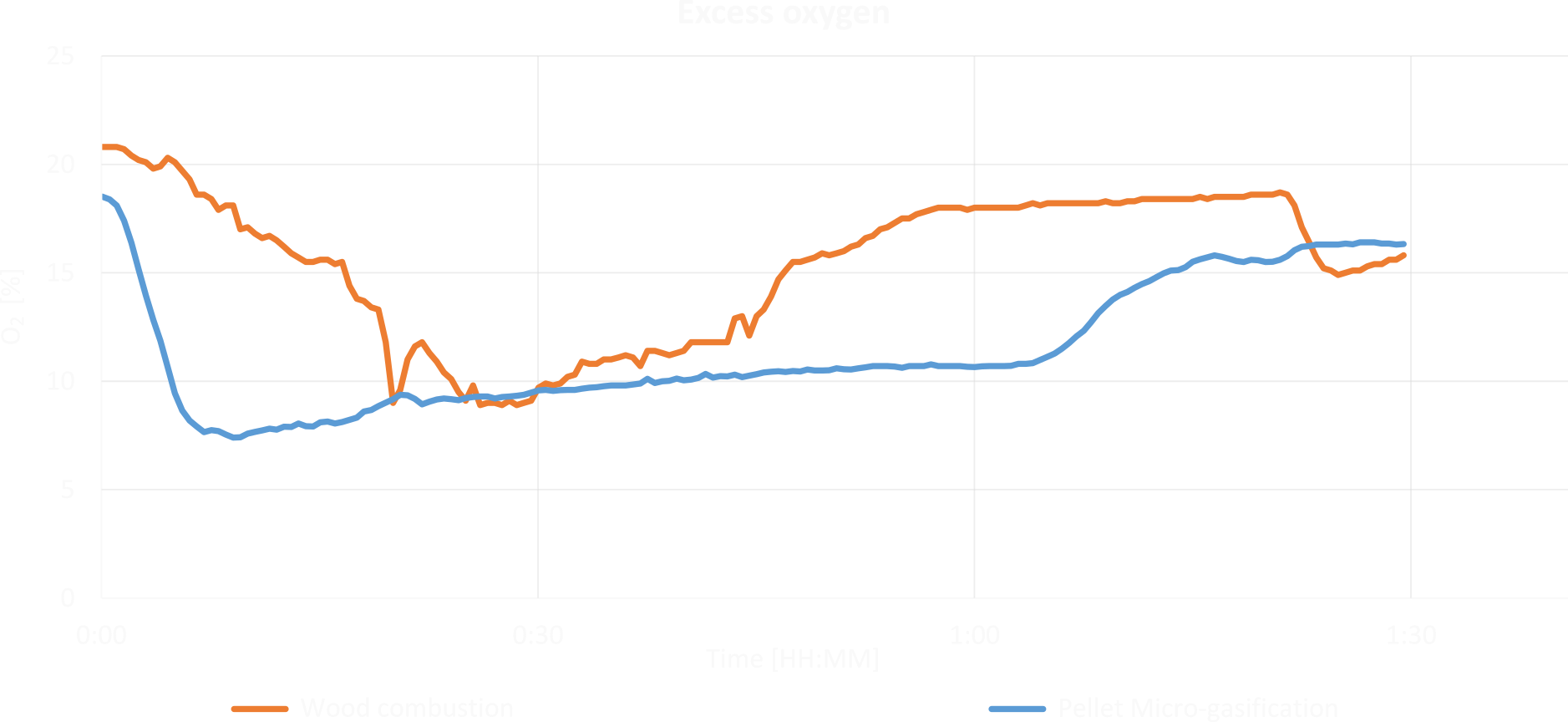

Thanks to the patented system, combustion takes place with a reduced supply of combustion air: the improved mixing of gases, guaranteed by the injection system, allows the entire process to take place with a reduced amount of excess oxygen.

The excess oxygen that does not take part in the thermal reactions but instead flows inside the stove heats up, and as it rises through the chimney, it takes some of the heat away, thus reducing efficiency: limiting it without compromising the combustion parameters allows less energy to be lost.

This advantage allows Blucomb burners to optimise the performance of the stove and produces a significant improvement in combustion efficiency in the unit.

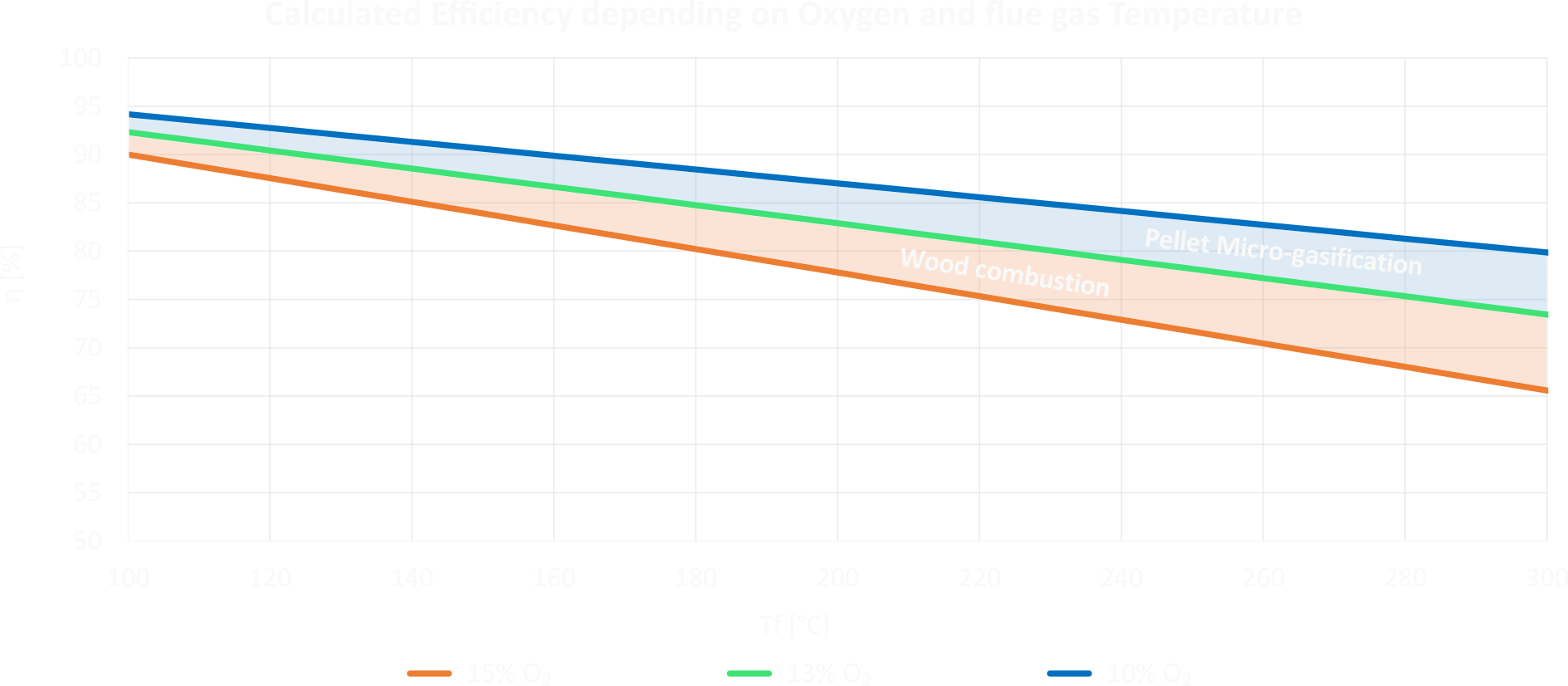

The actual efficiency of a stove is therefore given by its combustion efficiency and its ability to absorb heat from the exhaust gases and transmit it to the environment to be heated. The graph shows the trend of the actual efficiency as a function of these two parameters.